Effective Inventory Management: From Forecasting to Control

Effective inventory management is crucial for the success of any business, ensuring that products are available to meet customer demand while minimizing excess stock. The process involves multiple steps, from accurate forecasting to stringent control measures. Each stage plays a vital role in maintaining a balance between supply and demand, ultimately contributing to the company's profitability and efficiency.

Accurate Forecasting

The first step in effective inventory management is accurate forecasting. This involves predicting future demand based on historical data, market trends, and seasonality. Accurate forecasts help businesses maintain the right amount of stock, reducing the risk of overstocking or stockouts. Advanced forecasting techniques, including statistical models and machine learning algorithms, can provide more precise predictions, enabling businesses to make informed decisions.

Inventory Optimization

Once demand is forecasted, the next step is inventory optimization. This process involves determining the optimal order quantities and timing to minimize holding and ordering costs. Techniques such as Economic Order Quantity (EOQ) and Just-In-Time (JIT) inventory can be employed to ensure that inventory levels are kept at an optimal balance. Implementing these methods helps in reducing waste, improving cash flow, and increasing efficiency.

Technology Integration

The integration of technology into inventory management systems has revolutionized the way businesses operate. Inventory management software provides real-time data on stock levels, sales patterns, and supplier performance. These systems can automate various tasks, such as reordering stock when it reaches a certain level, thus reducing manual errors and improving accuracy. Barcoding and RFID technology further enhance the tracking and management of inventory.

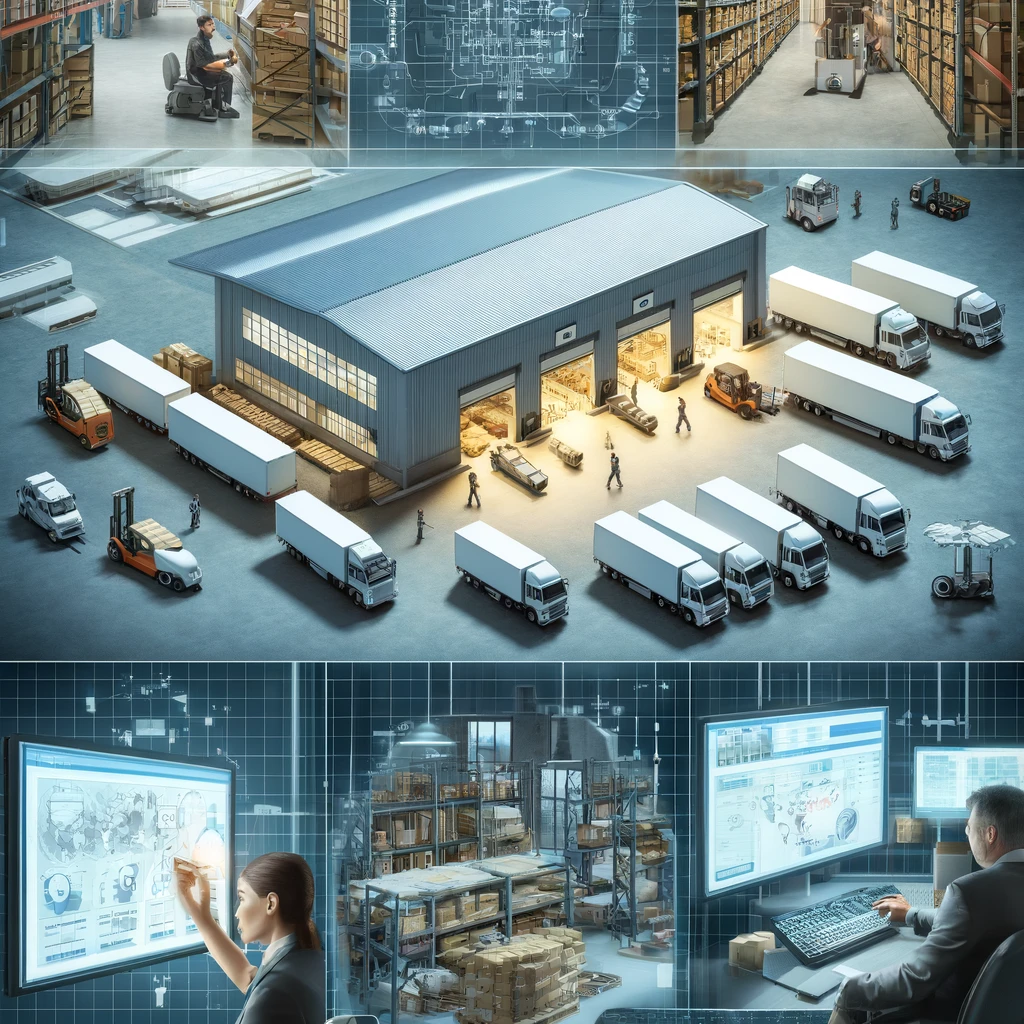

Warehouse Management

Efficient warehouse management is a critical component of inventory control. Organized storage, clear labeling, and effective layout design can significantly reduce the time taken to locate and retrieve items. Implementing warehouse management systems (WMS) can optimize space utilization, streamline picking processes, and ensure accurate stock counts. These systems often include features like real-time inventory tracking and automated replenishment.

Inventory Control Techniques

Effective inventory control techniques are essential to maintain the integrity of stock levels. Regular audits and cycle counts help in identifying discrepancies between physical stock and inventory records. Implementing ABC analysis allows businesses to prioritize high-value items that require more stringent control measures. Additionally, setting reorder points and safety stock levels ensures that there is always enough inventory to meet demand without overstocking.

Continuous Improvement

Inventory management is not a one-time task but a continuous process that requires regular review and improvement. Analyzing performance metrics and key performance indicators (KPIs) can highlight areas that need enhancement. By adopting a culture of continuous improvement, businesses can refine their inventory management practices, adapt to changing market conditions, and stay competitive.

In conclusion, effective inventory management encompasses a range of activities from accurate forecasting to stringent control measures. By optimizing each stage of the process, businesses can ensure that they meet customer demands efficiently while minimizing costs and maximizing profitability.